Lifting equipment is used to lift loads vertically. Rigging equipment supports and stabilizes loads during lifting or moving.

Lifting and rigging equipment are crucial in construction, manufacturing, and transportation industries. Lifting equipment includes cranes, hoists, and jacks, designed to move heavy loads vertically. Rigging equipment, such as slings, shackles, and chains, ensures the stability and control of loads during lifting or moving processes.

Proper use of both types of equipment ensures safety and efficiency. Understanding their differences helps in selecting the right tools for specific tasks. Regular inspection and maintenance of lifting and rigging equipment are vital for preventing accidents and ensuring longevity. Investing in high-quality equipment and training personnel can significantly enhance operational safety and productivity.

Introduction To Lifting And Rigging

Lifting and rigging equipment play crucial roles in material handling. They ensure safety and efficiency in various industries. Lifting equipment includes tools like cranes and hoists. Rigging equipment involves slings, chains, and other accessories. Understanding their differences is essential for proper usage.

Core Functions In Material Handling

The primary function of lifting equipment is to move heavy loads vertically. It includes devices like:

- Cranes

- Hoists

- Forklifts

Rigging equipment supports and stabilizes loads during lifting. It includes items like:

- Slings

- Shackles

- Chains

Historical Evolution Of Lifting And Rigging

Lifting and rigging have ancient roots. Early civilizations used simple machines. Pulleys and levers were common in ancient Egypt. In the Industrial Revolution, lifting technology advanced rapidly. Steam-powered cranes emerged, changing construction and manufacturing.

Modern lifting and rigging equipment are now highly specialized. They incorporate advanced materials and technologies for enhanced safety and efficiency. Today, these tools are indispensable in various sectors, from construction to logistics.

Credit: www.maximcrane.com

Lifting Equipment Essentials

Understanding lifting equipment essentials is crucial for safe and efficient operations. Lifting equipment includes various tools and devices designed to lift, lower, and move loads. Knowing the types and safety features of lifting equipment can enhance workplace safety and productivity.

Categories Of Lifting Devices

Lifting devices come in different forms, each suited for specific tasks. Here are the main categories:

- Hoists: Devices used to lift and lower loads with a drum or lift-wheel.

- Cranes: Machines equipped with a hoist, wire ropes, or chains for lifting and lowering materials.

- Winches: Mechanical devices that pull in, let out, or adjust the tension of a rope or wire rope.

- Jacks: Mechanical devices used to lift heavy loads by applying force via a screw thread or hydraulic cylinder.

- Slings: Flexible lifting devices made from chains, ropes, or webbing, used to secure loads.

Safety Features And Standards

Safety features and standards ensure the proper use of lifting equipment. Key safety features include:

- Load Limits: Each lifting device has a maximum load capacity.

- Braking Systems: Prevent accidental load release during lifting or lowering.

- Emergency Stop: Allows operators to halt the equipment in an emergency.

- Overload Protection: Devices to prevent overloading, which could cause equipment failure.

Compliance with safety standards is essential. Important standards include:

- OSHA (Occupational Safety and Health Administration): Sets regulations for workplace safety, including lifting equipment.

- ASME (American Society of Mechanical Engineers): Provides standards for the design and use of lifting equipment.

- ISO (International Organization for Standardization): Offers global standards for lifting equipment safety and performance.

Rigging Equipment Explained

Understanding rigging equipment is crucial for safe lifting operations. Rigging involves securing and moving heavy loads. This requires specialized hardware to ensure stability and safety.

Types Of Rigging Hardware

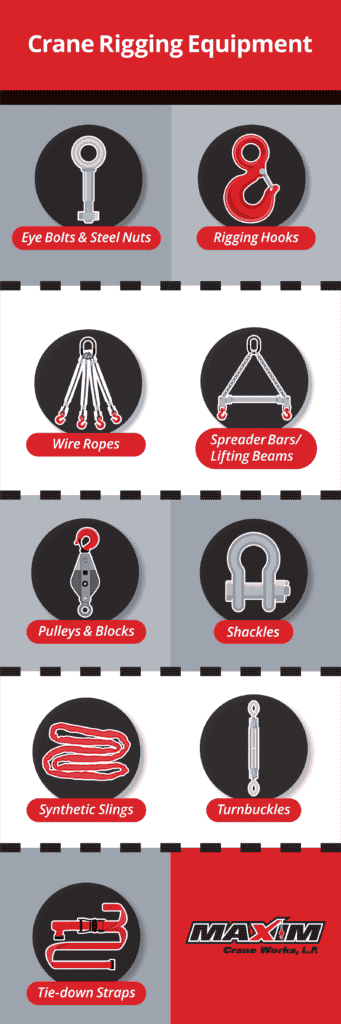

Rigging hardware comes in various forms. Each has a specific use in lifting and moving loads.

- Shackles: Used to connect slings, ropes, and chains.

- Slings: Made from wire, chain, or synthetic materials. Used to lift loads.

- Hooks: Attach to loads for lifting. Come in various shapes.

- Eye Bolts: Used to anchor rigging hardware to a load.

- Turnbuckles: Adjust the tension of ropes and cables.

Material And Design Considerations

Rigging equipment must be strong and durable. The material and design affect the performance and safety.

| Material | Attributes |

|---|---|

| Steel | High strength and durability. Suitable for heavy loads. |

| Aluminum | Lightweight but strong. Used for lighter loads. |

| Synthetic Fibers | Flexible and lightweight. Used for delicate loads. |

Design factors also play a significant role. Rigging hardware must have proper load ratings. This ensures they can handle the specific weights and forces during operations.

Regular inspection is crucial. Look for signs of wear and tear. Replace damaged equipment to maintain safety.

Key Differences Between Lifting And Rigging

Understanding the differences between lifting and rigging equipment is vital for any construction or industrial project. Both play significant roles in ensuring the safe and efficient movement of heavy loads. This section will delve into the key differences between lifting and rigging, focusing on operational roles, responsibilities, load limits, and equipment durability.

Operational Roles And Responsibilities

Lifting involves moving loads vertically. It requires equipment like cranes, hoists, and lifts.

- Cranes: Used for heavy loads and long distances.

- Hoists: Ideal for smaller loads.

- Lifts: Used in confined spaces.

Rigging involves securing and stabilizing loads. It uses slings, chains, and ropes.

- Slings: Flexible and adaptable for various loads.

- Chains: Strong and durable for heavy loads.

- Ropes: Versatile for different applications.

Load Limits And Equipment Durability

Lifting equipment has specific load limits. Exceeding these can lead to failures.

| Equipment | Load Limit |

|---|---|

| Cranes | Up to 300 tons |

| Hoists | Up to 10 tons |

| Lifts | Up to 2 tons |

Rigging equipment also has load limits but focuses on stability.

| Equipment | Load Limit |

|---|---|

| Slings | Up to 50 tons |

| Chains | Up to 100 tons |

| Ropes | Up to 20 tons |

Durability is crucial. Lifting equipment often handles dynamic forces, requiring high durability. Rigging focuses on maintaining load stability and preventing swaying.

Compliance And Regulations

Compliance and regulations are critical in the lifting and rigging industry. They ensure safety and efficiency. Without proper adherence, accidents can happen. This section explores the industry standards, certification, and training requirements.

Industry Standards For Safe Operations

Industry standards provide guidelines for safe operations. They are set by organizations like OSHA and ANSI. These standards cover equipment specifications and operational procedures.

Following these standards reduces risks. They ensure lifting and rigging equipment is used correctly. This includes proper load limits and regular inspections.

Certification And Training Requirements

Certification ensures workers know how to handle equipment. Training programs are essential. They teach the correct use of lifting and rigging tools.

- Basic Training: Covers equipment types and basic operations.

- Advanced Training: Focuses on complex operations and problem-solving.

- Ongoing Training: Keeps skills updated with the latest standards.

| Certification Type | Required Hours | Renewal Period |

|---|---|---|

| Basic Certification | 40 hours | 2 years |

| Advanced Certification | 60 hours | 3 years |

Proper training reduces the risk of accidents. It ensures equipment is handled safely. Certified workers are more reliable and efficient.

Maintenance And Inspection

Proper maintenance and inspection are crucial for ensuring the safety and efficiency of both lifting and rigging equipment. Regular checks help identify potential issues early, preventing accidents and costly repairs. Understanding the different protocols for these types of equipment can enhance their lifespan and performance.

Routine Checklists For Lifting Gear

Creating a routine checklist for lifting gear helps maintain safety standards. This checklist should include several key points.

- Visual Inspection: Look for any visible damage or wear.

- Operational Test: Ensure the equipment functions correctly.

- Lubrication: Apply grease to moving parts as needed.

- Load Testing: Test the equipment under load conditions to verify performance.

Documenting these checks can help track the condition of the gear over time.

Inspection Protocols For Rigging Components

Rigging components require a different set of inspection protocols. Here are some essential steps:

- Component Checks: Inspect hooks, shackles, and slings for damage or deformation.

- Certification Verification: Ensure that components meet safety standards and certifications.

- Wear and Tear: Check for signs of wear, such as fraying or corrosion.

- Connection Points: Examine the connection points for stability and security.

Following these protocols can significantly reduce the risk of accidents.

Both lifting and rigging equipment require rigorous and regular maintenance and inspection to ensure optimal performance and safety.

Common Applications In Industries

Lifting and rigging equipment are crucial in many industries. They ensure safe and efficient handling of heavy loads. Understanding their common applications can help in selecting the right equipment.

Construction And Engineering

Construction sites rely heavily on lifting and rigging equipment. Cranes and hoists are used to move heavy materials like steel beams and concrete blocks. Slings and shackles are essential for securing loads.

| Equipment | Use |

|---|---|

| Cranes | Moving large materials |

| Hoists | Lifting heavy loads vertically |

| Slings | Securing and lifting loads |

| Shackles | Connecting lifting equipment |

Maritime And Offshore

Maritime and offshore industries use specialized lifting and rigging equipment. Winches and derricks are vital for handling cargo on ships and oil rigs. Chains and ropes ensure secure and reliable operations.

- Winches: Used for pulling and lifting loads on ships.

- Derricks: Essential for lifting heavy equipment on oil rigs.

- Chains: Provide strong and secure lifting connections.

- Ropes: Used for various lifting and securing tasks.

Choosing The Right Equipment

Choosing the right equipment for lifting and rigging is crucial for safety and efficiency. The correct gear ensures smooth operations and minimizes risks. This section will guide you on how to select the best equipment based on your needs.

Assessment Of Load And Environment

First, evaluate the load you need to lift. Consider its weight, size, and shape. Different loads require different lifting tools. For example, a heavy load may need a crane, while a smaller load might only need a hoist.

Next, examine the environment where the lifting will occur. Is the area confined or open? Is it a construction site or a warehouse? The environment impacts the choice of equipment. For instance, an open site might allow for larger machinery.

Here is a quick table for reference:

| Load Type | Recommended Equipment |

|---|---|

| Heavy and Large | Crane |

| Medium Weight | Forklift |

| Small and Light | Hoist |

Cost-benefit Analysis Of Equipment Selection

Conduct a cost-benefit analysis before selecting equipment. Balance the initial cost against the long-term benefits. Investing in high-quality gear can save money in the long run.

- Initial Cost: Consider the purchase price or rental fees.

- Maintenance: High-quality equipment often requires less maintenance.

- Efficiency: Better tools can increase productivity.

- Safety: Safer equipment reduces the risk of accidents.

Here’s a simple comparison:

| Factor | High-Quality Equipment | Low-Quality Equipment |

|---|---|---|

| Initial Cost | High | Low |

| Maintenance | Low | High |

| Efficiency | High | Low |

| Safety | High | Low |

Case Studies

Understanding the difference between lifting and rigging equipment is crucial. Case studies can provide real-world insights into their applications and challenges. These case studies highlight both successes and failures, offering valuable lessons for professionals in the field.

Success Stories In Heavy Lifting

Heavy lifting often involves complex machinery and precise calculations. These success stories demonstrate the effectiveness of proper planning and execution.

- Project Alpha: A construction company used a 100-ton crane to lift steel beams. The project was completed ahead of schedule. The team ensured safety protocols were in place. This led to zero accidents and high efficiency.

- Bridge Construction: Engineers lifted and placed concrete segments for a new bridge. They used synchronized hydraulic jacks. The precision was remarkable, and the bridge opened to traffic on time.

- Wind Turbine Installation: A team lifted turbine blades using specialized equipment. The operation required careful coordination. The project saw a 20% increase in productivity due to the right tools.

Lessons Learned From Rigging Failures

Rigging failures often result from inadequate preparation or the wrong equipment. These lessons highlight the importance of meticulous planning and the right tools.

- Factory Mishap: A factory experienced a rigging failure during equipment relocation. The workers used an undersized sling, which snapped under pressure. This incident underscored the need for proper equipment assessment.

- Maritime Disaster: A ship’s cargo rigging failed, causing significant delays and losses. The wrong rigging configuration was to blame. This case emphasized the importance of using industry-standard practices.

- Warehouse Collapse: A warehouse structure collapsed due to incorrect rigging of support beams. The team overlooked load calculations. This failure highlighted the critical role of accurate load assessments in rigging.

Credit: www.connect-knkt.com

Future Trends In Lifting And Rigging Technology

The lifting and rigging industry constantly evolves. Future trends promise exciting advancements. New technologies enhance safety, efficiency, and productivity. Let’s explore these trends.

Innovations In Equipment Design

Equipment design has seen significant innovations. Lightweight materials are now used in rigging gear. These materials reduce weight and increase strength. Composite materials are replacing traditional steel. They offer durability and corrosion resistance.

Ergonomic designs improve operator comfort and safety. Controls are more intuitive. This reduces the risk of accidents. Smart sensors are embedded in equipment. They monitor load conditions and alert operators to potential issues.

Automation And Robotics In Material Handling

Automation is transforming material handling. Robotic systems are increasingly used in lifting and rigging tasks. They handle heavy loads with precision. Robots reduce the need for manual labor.

Automated Guided Vehicles (AGVs) are becoming common in warehouses. They transport materials without human intervention. Drones are also emerging in the industry. They inspect rigging setups and monitor safety from above.

| Trend | Benefit |

|---|---|

| Lightweight Materials | Increased strength, reduced weight |

| Smart Sensors | Real-time monitoring, enhanced safety |

| Robotics | Precision, reduced manual labor |

| AGVs | Efficient material transport |

| Drones | Inspection and safety monitoring |

The future of lifting and rigging technology is bright. Innovations in design and automation offer many benefits. They enhance safety, efficiency, and productivity in the industry.

Credit: www.lagrangecrane.com

Frequently Asked Questions

What Is The Difference Between Rigging And Lifting?

Rigging involves setting up equipment to lift objects safely. Lifting is the actual process of moving objects using hoists or cranes.

What Is Rigging Equipment?

Rigging equipment includes tools and devices used to lift, move, and secure heavy loads. Common items are ropes, chains, slings, and hoists.

What Is The Difference Between Lifting Gear And Lifting Equipment?

Lifting gear refers to accessories like slings and shackles. Lifting equipment includes machinery like cranes and hoists. Both facilitate lifting operations.

What Is The Difference Between Rigger And Rigging?

A rigger is a person who sets up and operates rigging equipment. Rigging refers to the system of ropes, chains, and other gear used for lifting and moving heavy objects.

Conclusion

Understanding the difference between lifting and rigging equipment is crucial for safety and efficiency. Lifting equipment moves loads vertically, while rigging equipment supports and secures these loads. Choosing the right tools ensures successful and safe operations. Always consult experts and follow regulations to minimize risks.

Proper knowledge and equipment lead to safer work environments.